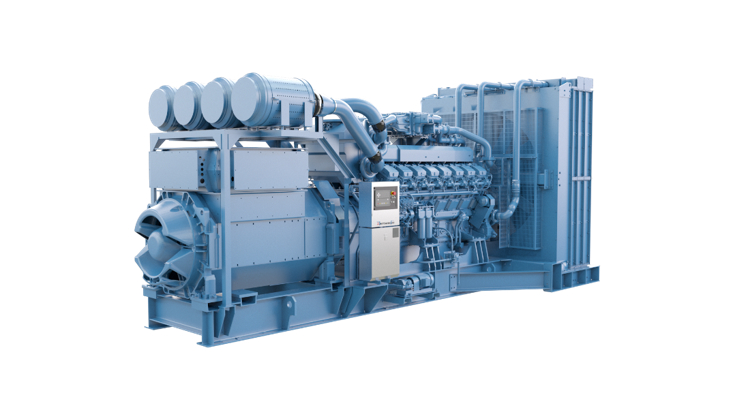

Mitsubishi Heavy Industries Engine System Asia (MHIES-A) is proud to present its new model in Mitsubishi Generator Series (MGS-R) lineup designed for 50Hz markets. The new MGS3100R, the most powerful 16 cylinder industrial diesel generator on the market. Equipped with Mitsubishi original common rail system that optimize fuel consumption and emission.

This new low emission generator set are catered for emergency service and target critical power applications- such as airports, healthcare, water treatment plants and hyperscale data centers. “Expanding our line of MGS generator set is part of our group strategy,” said Kwan Kok Feei, Head of Engineering at MHIES-A. “This allows us to expand the range of MGS-R lineup while offering a competitive product and driving a significant reduction in product footprint and fuel consumption.”

This new MGS3100R generator set is powered by Mitsubishi S16R2-PTAWT-CR diesel engine with bore and stroke dimensions of 170/220 mm for an overall displacement of 79.90L. The V-type sixteen-cylinder engine is turbocharged and charge-air cooled and delivers a maximum output of 3521bhp at 1500rpm. “The design and engineering specification of this engine is developed by the Mitsubishi Heavy Industries Engine & Turbocharger team and these engines will be built exclusively into MGS generator applications,” Kwan said.

The Mitsubishi engines drive 4-pole, rotating field brushless permanent magnet alternators through double bearing. The pilot excited alternators are engineered to deliver excellent load response, Kwan said, along with superior short circuit capability of up to 300% of rated current for up to 10 seconds.

The gen-sets is equipped with DSE7310 controller, built by Deepsea, engine electronic control module from Woodward, digital voltage regulator and Mitsubishi developed datalogger that provide advanced control, system monitoring, protections and system diagnostics.

Both gen-sets are available with three levels of sound attenuating enclosures and residential, critical and hospital grade silencers, along with subbase fuel tanks in various capacities. The enclosures incorporate MHIES-A’s fade-, scratch- and corrosion-resistant MGS Power Armor automotive-grade textured finish. Like all of MGS gen-sets, the new MGS3100R are approved for use with certified renewable hydrotreated vegetable oil (HVO) and renewable diesel (RD) fuels compliant with EN15940/ASTM D975 standards. No adaptation is needed and both HVO and diesel fuel can be mixed together, MHIES-A said, adding that HVO is highly stable, with no sensitivity to oxidation and can be stored long-term. The new gen-sets are being built at MHIES-A’s facilities in Singapore.